The Dos and Don'ts of Using a Bending Brake

Bending brakes offer a quick and easy way to manipulate the shape of sheet metal. Also known as metalworking brakes, they are heavy-duty machines with a set of clamps or rollers. As you feed sheet metal through it, the bending brake will bend it. While bending brakes are relatively simple, though, there are certain dos and don'ts you should follow when using a bending brake.

Do Wear Gloves

Always wear gloves when using a bending brake. Hand injuries in the workplace. According to the U.S. Department of Labor (DOL), nearly one-quarter of all work-related injuries involve the hands and/or fingers. Bending sheet metal is a hands-on activity. You'll have to hold the sheet metal and move it to the bending brake. Gloves will protect your hands from sharp edges or protrusions that could otherwise cause injury.

Do Wear Eye Protection

In addition to gloves, you should wear eye protection when using a bending brake. Bending sheet metal may result in shrapnel. As the sheet metal bends, pieces of it may shoot out. Eye protection will protect your eyes from these projectiles.

Do Remove Burrs Before Bending

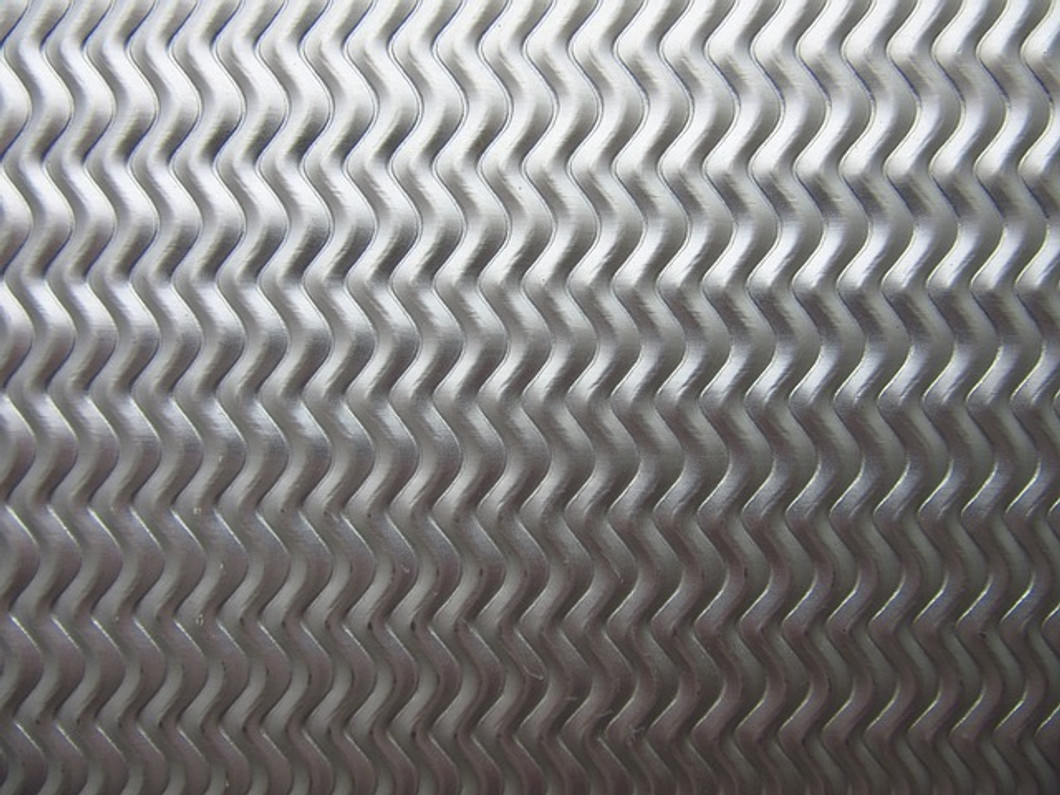

If you discover any burrs on the sheet metal, you should remove them before attempting to bend the sheet metal. Burrs are jagged ridges on the edges or surface of sheet metal. When sheet metal is initially produced, it may contain burrs. Bending sheet metal with the burrs intact may result in bodily injury. For safety purposes, remove all burrs from the sheet metal before attempting to bend it.

Don't Wear Loose-Fitting Clothing

Like with other heavy-duty machines, you should avoid wearing loose-fitting clothing when using a bending brake. Loose-fitting clothing may get stuck in the clamps or rollers. If you wear a baggy, long-sleeve shirt, for instance, the excess fabric at the cuffs may get stuck in the bending brake. To lower the risk of bodily injury, avoid loose-fitting clothing such as this.

Don't Insert Sheet Metal at an Angle

Another mistake to avoid when using a bending brake is inserting sheet metal at an angle. You shouldn't feed the sheet metal from above or below the bending brake. The correct way to use a bending brake is to insert the sheet metal so that it's parallel to the bending brake. You can raise or lower the sheet metal after inserting it into the bending brake, but you should always begin by feeding the sheet metal so that it's parallel to the bending brake initially.

Recent Posts

-

Fire Safety in the Workplace: What You Need to Know

What steps are you taking to prevent fires in your workplace? According to the U.S. Occupational Saf …Aug 23rd 2023 -

Is It Safe to Go Jogging With a Cold Infection?

If you're suffering from a cold infection, you might be wondering whether it's safe to go jogging. T …Aug 22nd 2023 -

5 Safety Tips to Follow When Using a Powder-Actuated Tool

Powder-actuated tools are commonly used to join materials to steel and concrete. Also known as Hilti …Aug 20th 2023