FallTech

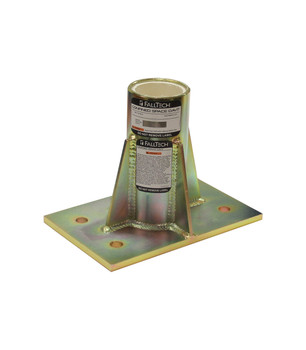

FallTech 65020BFZ Flush-mount Fixed Base Zinc for Confined Space Davit - 1 Each

- SKU:

- FL-65020BFZ

- Availability:

- Ship 3-5 business days

- Weight:

- 23.00 LBS

- Width:

- 1.00 (in)

- Height:

- 1.00 (in)

- Depth:

- 1.00 (in)

- Shipping:

- Calculated at Checkout

Bulk discount rates

Below are the available bulk discount rates for each individual item when you purchase a certain amount

| Buy 5 or above | and get 5% off |

Description

Allows for bolt-in installations into any existing concrete or steel structure and provides a smooth and flush finish that eliminates trip hazards.

Features:

- For use in existing concrete or steel structures

- Bolt-on installation

- Flush floor profile is ideal for high traffic areas and reduces tripping hazards

- Zinc Plated Steel with PVC sleeve insert

GENERAL SPECIFICATION:

- Rated Capacity (Work load): 620 lbs (281 kg) @ Minimum 4:1 Design Factor

- Mast Moment Proof Load: 74,000 in-lbs (8,861 Nm)

- Mast Rotation: 360°

- Weight (with sleeve insert): 22 lbs (10 kg)

MATERIALS AND CONSTRUCTION:

- General Construction: Welded Steel/SS

- Base-Plate Material: A-36 Steel Plate/304 SS

- Sleeve Material: Sch. 40 Pipe/304 SS

- Sleeve Insert Material: PVC Pipe, ASTM-D-1785

- Finish (Steel): Zinc Plated

- Finish (SS): Bead Blasted

- Plating Specification (Zinc): ASTM B633-13, Type III, SC2, Yellow

MINIMUM MOUNTING REQUIREMENTS:

- Concrete Thickness: 9.5 in (241 mm)

- The structure and mounting hardware must be capable of withstanding a 74,000 in-lbs (8,361 Nm) moment and a 5,000 lb (2268 kg) vertical load.

- Installation MUST comply with local regulation standards and be approved by a qualified engineer before use.

- To be used in conjunction with the FallTech Davit System only.

APPLICATION RESTRICTIONS:

1. Sleeves are to be used with masts and accessories manufactured by FallTech ONLY.

2. System Design factor depends on other system components and the configuration in which they are assembled. The minimum

design factor for all standard FallTech safety systems masts and accessories is 4:1.

3. Allow welding to be carried out by qualified personnel.

4. If base material fails to meet minimum requirements, a reinforcement MUST BE added in order to meet minimum requirements.

5. Each installation MUST comply with local regulation standards and be approved by a qualified engineer before use.

PRE-USE INSPECTION:

Inspect the Bolt-On Flush Mount Sleeve thoroughly for damage, inspection should include checking for dents, cracks, deformed or bent tubing and welded areas for cracks.

Do not use if the Bolt-On Flush Mount Sleeve if it fails any part of this inspection.